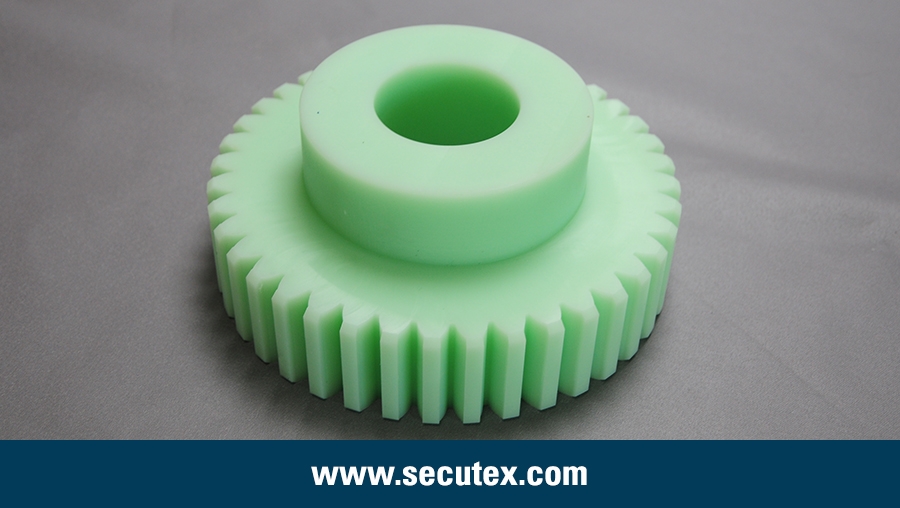

Made from a single mould

Worm screws, gear wheels, slide rails and other technical mouldings are today made of engineering plastics such as POM (polyoxymethylene), PA (polyamide) or PE (polyethylene). These materials with different property profiles (negative high water absorption with PA, poorer wear behaviour with PE) are supplied as sheets or rods. The required moulded parts are then produced by mechanical processing (turning, milling etc.) in a more or less complex manner. Effective injection moulding is only worthwhile for large quantities together with small component sizes, otherwise the high tool costs cannot be amortized.

secutex-Techno is characterised by high hardness (70° Shore D) and rigidity over a wide temperature range. It retains its high toughness down to -30 °C, has a high abrasion resistance and a low coefficient of friction.

The intrinsic colour is yellow, making it well suited for technical applications. Mechanical processing is simple and comparable with other hard plastics.

With secutex-Techno, the required moulded parts can be produced simply and inexpensively in simple casting moulds, eliminating the need for time-consuming machining. Mounting holes can be

The delivered components can therefore be mounted directly. The secutex-Techno material can be specifically cast into secutex moulds according to customer drawings. Customers can also order secutex-Techno in short lengths for further processing and are therefore not dependent on the usual dimensions of sheet material.