Standard

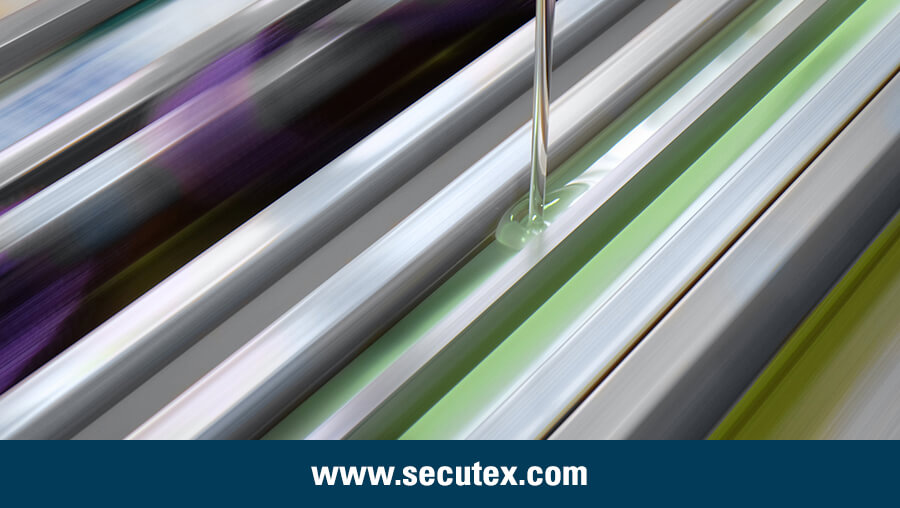

secutex supplies the polyurethanes transparent as well as yellow and red coloured.

Special colours

secutex can supply polyurethane products in different colours. When colouring polyurethane, it is important that the colour chemically blends into the sensitive system so that the product properties remain unchanged. In addition, when choosing the colour, it must be taken into account that the base materials usually have a brown-yellow basic colour.

However, all colours are possible as an option, whereby it must be taken into account that the time and effort required in production for cleaning the casting machine is significant. Special colours are therefore only cost-effective if a larger quantity is ordered.

Polyurethanes age, as most plastics do, and colour stability cannot be guaranteed in any case. It is recommended to choose colours from the ranges RED or even better YELLOW. Red becomes orange, yellow becomes more yellow. Colours like green or blue are probably more critical

Yellowing

Polyurethane yellowing due to exposure to light (both daylight and also artificial). The discoloration is caused by the oxidation of certain molecular groups in the material. Yellowing due to the influence of light is lower in polyester-based polyurethanes than in polyether-based polyurethanes, but this yellowing does not affect the physical-mechanical properties of the material.

The addition of colour and/or anti-yellowing agent can delay the yellowing of the polyurethane, but cannot stop it completely. With the anti-yellowing agent it is important that the material chemically blends into the polyurethane so that the product properties remain unchanged.

SpanSet secutex Sicherheitstechnik GmbH

Am Forsthaus 33

52511 Geilenkirchen, Deutschland

Telefon +49 2451 48 45 73 0