Plastic for welding …

Welding is often the simplest and best way of fastening. The range of different perforated plates offers a wide range of applications.

Size and quantity of the welding joints depend on the substructure and must be defined on site. Please note that the perforated metal sheet can under no circumstances take over any static functions. The secutex buffer pad is simply disconnected by grinding away the welding spots.

These are the advantages:

Applications:

Examples:

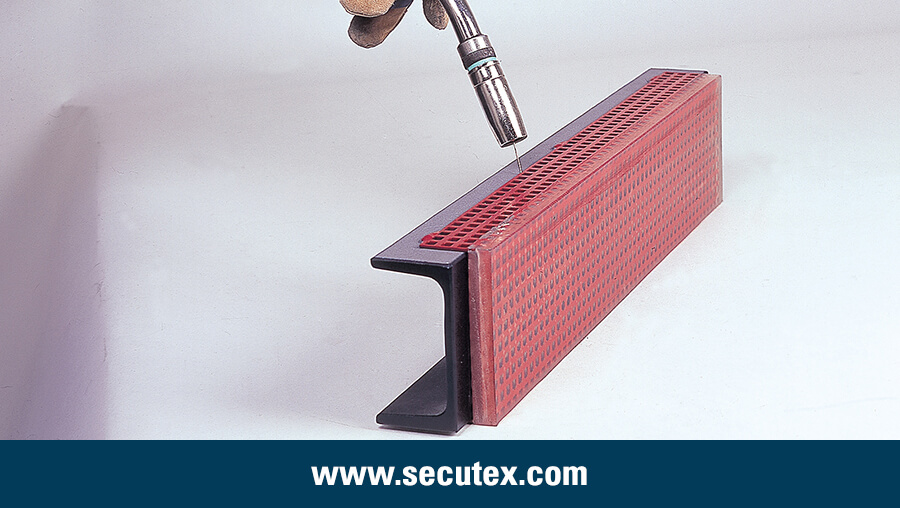

1. Perforated metal sheet, overhang at the side

This version is suitable for welding onto flat surfaces and extra-wide profiles of construction steel. The impact protection is placed on top and spot-welded at the sides. There is no faster way to do it!

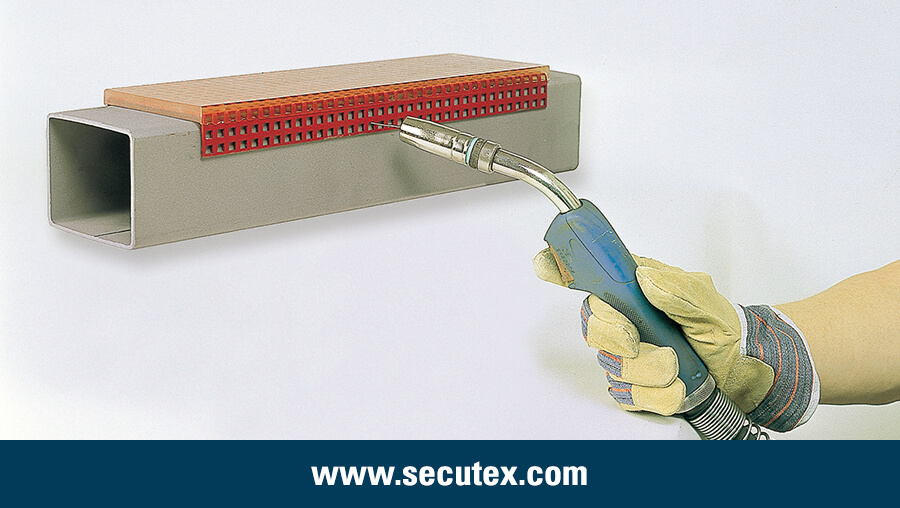

2. Perforated metal sheet, bent at 90°

This version is suitable for welding onto beams and square tubes of construction steel. The impact protection is placed on top and spot-welded to the side. There is no faster way to do it!

A practical Tip:

Use a small, edged piece of copper or normal steel sheet to protect the secutex material against the heat when making the spot-welds

SpanSet secutex Sicherheitstechnik GmbH

Am Forsthaus 33

52511 Geilenkirchen, Deutschland

Telefon +49 2451 48 45 73 0