secutex – the gentle power against raw impact forces.

If screwing or welding is not possible, just glue the secutex where impact protection is required. No problem with the secutex special bonding material.

These are the advantages:

Applications:

Examples:

A proper bond requires always a good preparation …

The following procedure is needed:

1. Cleaning of the surface

Suitable grease and silicone-dissolving cleaning agents are required. This step is important to ensure that there is no dirt on the surface which may be present during the grinding or sandblasting process.

2. Roughening the surface

Sandblasting or grinding of the surface are especially suitable here. The right procedure must be defined on site. Roughening enlarges the surface and significantly improves the bonding result.

3. Cleaning the surface, again

Suitable grease and silicone-dissolving cleaning agents are required. This step is important to remove the dirt caused by roughening the surface.

4. Cleaning the secutex buffer pad

Suitable grease and silicone-dissolving cleaning agents are required. This step is important in order to remove possible soiling of the surface.

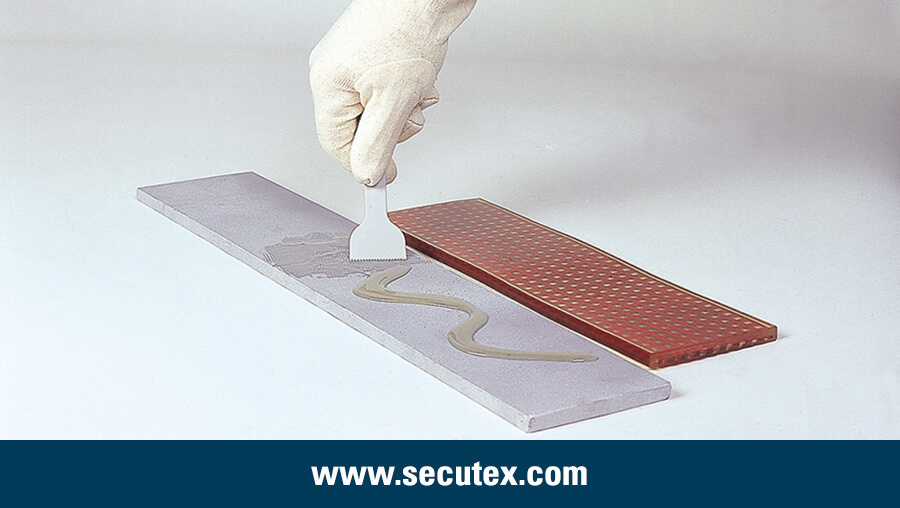

5. Application of the adhesive

Apply the selected adhesive according to the relevant instructions. A good room temperature is always needed, the item and secutex should not be cold. The adhesive should be applied as thin as possible.

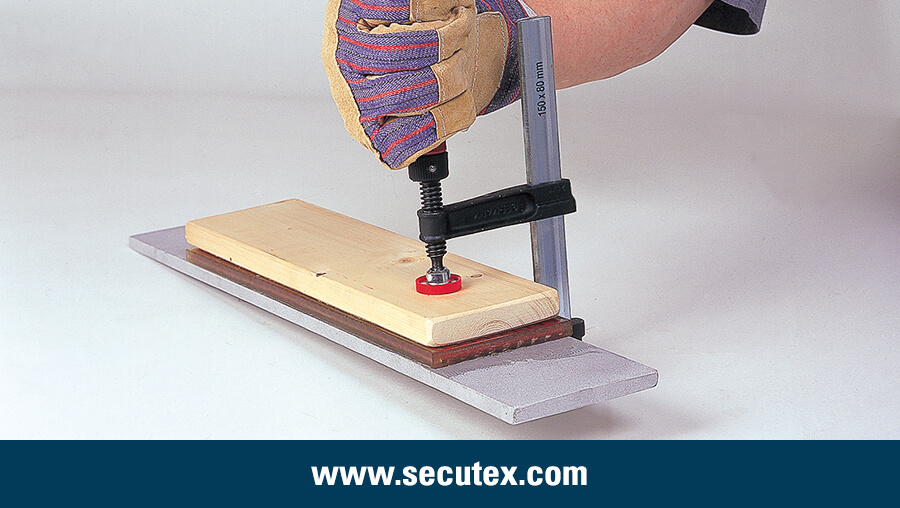

6. Pressure application

The impact protection must be pressed flat and permanently onto the item. For this purpose, tools such as wooden planks and screw clamps are suggested. The contact pressure must be maintained during the reaction time specified for the adhesive.

A practical Tip:

SpanSet secutex Sicherheitstechnik GmbH

Am Forsthaus 33

52511 Geilenkirchen, Deutschland

Telefon +49 2451 48 45 73 0